Encoders for Brushless DC Motors Save Production Time

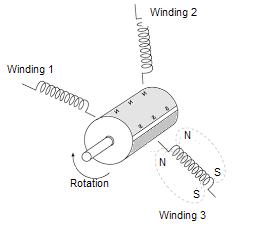

Motion control applications use encoders to translate position, or motion of a shaft or axle, to analog or digital output signals. Applications that require a brushless DC motor also require an external system to commutate the rotor and stator poles of the motor.

BLDC motors use electrical commutation in combination with stators that incorporate a sequence of coils and permanent magnet rotors. Because they don’t have brushes to provide current switching, BLDC motors must rely on external controllers to provide the commutation that switches the current in the rotor coils to generate motion.

BLDC motors provide some important advantages:

- Efficiency increase of 15-20%

- Noiseless

- Reduced maintenance since there are no brushes

- Torque remains constant at all rated speeds

- Longer service life since there are no friction losses

Brushless DC motors are commonly used in applications such as industrial automation, transportation, aerospace, medical/healthcare and consumer electronics. As BLDC motors have increased in popularity, so has the need for real-time position feedback. Hall-effect sensors facilitate control of BLDC motors, but only for speed and direction. Incremental encoders are the typical solution for more accurate position information. Commutation encoders from Quantum Devices allow engineers to simplify motor design, and save OEMs money by reducing assembly costs in high-volume manufacturing.

QC201 Commutation Indicator

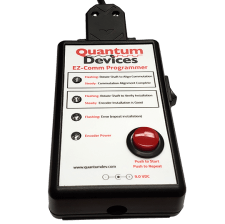

Our newest product, the QC201 commutation indicator, is perfect for high-volume commutation encoder alignment. The QC201 commutation indicator not only reduces the steps to time a motor to an encoder but also eliminates the need for a back-drive station, oscilloscope and a trained operator to set up and decipher the traces of an oscilloscope in order to calculate the offset.

Quantum Devices’ encoders have been designed to be timed with the QC201 commutation indicator. This is due to the synergy between the lithography of the custom photodiode arrays and the precision pattern of the code disc. The relative distance from the index pulse to the rising edge of the U channel is reliably known. With this known fixed location, the QC201 is able to use the incremental channels to determine the encoder’s commutation position in relation to the motor’s winding. This position is conveyed in electrical degrees of commutation on an easy-to-read LCD screen.

Brushless Encoder for Faster Commutation & Timing

BLDC motors have been in use for years, but until recently the need for complicated control and feedback circuitry has often made their application, installation and maintenance time consuming and difficult (here’s an example of timing alignment using back EMF).

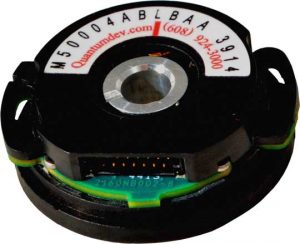

These difficulties have been eliminated with the introduction of Quantum Devices’ QM35 EZ-Comm, a low-profile rotary optical encoder that has a full complement of incremental and commutation signals built in to the base product.

The EZ-Comm features a programmable commutation offset facilitating fast installation and timing of the commutation channels to a BLDC motor. With standard pole counts of 4, 6, 8 and 10 and the handheld EZ-Comm Programmer unit, the QM35 EZ-Comm is a high-functioning programmable rotary encoder with a small footprint ideally suited to high-volume OEM applications.

Brushless Motor Controller Encoder Design Offers Advantages

QML 35 EZ-Comm encoder has programmable commutation & single-ended outputs

Other important features of the QM35 EZ-Comm and QML35 EZ-Comm commutation encoders for brushless DC motors:

- Bearingless modular design

- Low profile assembled height

- Resolutions up to 5000 lines per revolution

- 4, 6, 8, 10 or 14 pole commutation

- Easy lock-n-twist assembly feature

- Through bore sizes up to 0.375″ diameter

- Up to 1Mhz frequency response

- High noise immunity

- RoHS construction

- Hub to shaft uses two 3-48 set screws

- Hermetically sealed LED

- Multiple mounting options including resolver size 15

Miniature Brushless Encoder with Integrated Commutation

QM22 encoders with built-in commutation fit on NEMA 11 BLDC servo motors

Quantum Devices’ QM22 series of incremental encoders offers a super compact 22mm diameter and a 12.4 mm thickness along with built-in BLDC motor commutation signals. The QM22 is attractively priced and ideal for high-volume OEM applications. Learn more about our miniature rotary encoder for brushless servo motor control that sports big benefits.

Brushless Motor Encoders Made in USA

Quantum Devices manufactures high quality, high performance optical encoders at our vertically-integrated facility in Barneveld, Wisconsin. If you’re a brushless motor manufacturer looking for commutating encoders, get in touch for a quote. Our engineers are available to customize brushless DC motor encoders with custom line counts, commutations or bore sizes.